1 Introduction

The search for new final destinations for

residue from industrial processes has grown due to the interest of the

industries in searching for more viable alternatives in the economic and

environmental scope. Nowadays, it is known that the industries responsible for

the manufacture and transformation of materials produce, to a greater or lesser

degree, a certain amount of residue that is not always reused or has an ecologically

correct destination.

In the forestry sector, the generation of

residue has a significant impact, mainly for the pulp and paper industries,

which face environmental problems due to the significant generation of residue

from its production. According to Bellote et al. (1998), the generation of 48

tons of residue for every 100 tons of pulp produced makes it impossible to

choose landfills as final destination, due to the high maintenance and

implantation costs, as well as the need for handling with care recurring risks

of environmental contamination.

As an alternative to the landfill, the use

of industrial residue in agriculture has proved to be viable considering the

soil's potential to inactivate part of the chemical compounds present in such

residue, reducing its pollutant potential and, at the same time, the residue can

be used as low-cost agricultural inputs.

Residue from pulp and paper industries has

been highlighted when it comes to application to the soil and its consequences

for the various types of plantations. As evidenced by the studies carried out

in the area, the potential of the pulp and paper production residues is due to

the capacity to raise soil pH and to positively influence nutrient cycling,

functioning as a nutrient supply demanded by the crops (ALMEIDA et al. , 2008).

It is worth mentioning that the

characteristics of a residue generated by an industry depend directly on its

production process. In the pulp and paper sector, in general, the industrial

interest is the extraction of wood pulp, separating it from lignin, minerals

and resins, producing a pulp with high quality, with competitive prices and

with minimum environmental impact. There are different industrial methods that

realize the obtaining of cellulosic fibers, however it is highlighted as main

method the pulp kraft, which allows the obtaining of a pulp of high resistance

and with low lignin content, besides being distinguished for having as

principal the recovery of the chemicals used (FAVARO, 2015).

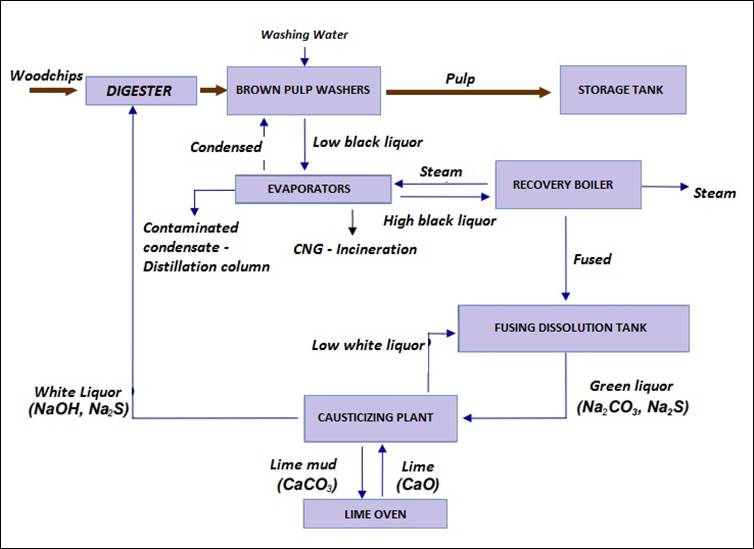

The pulping process using the kraft method

uses what is called a white liquor, formed of sodium hydroxide (NaOH) and sodium

sulfide (Na2S), for the digestion of wood lignin and the formation

of cellulose pulp. At the end of this stage, the black liquor is expelled from

the digester and has its composition based on: chemicals used, dissolved lignin

and carbohydrates. While pulp goes into the industrial process, it is necessary

that black liquor be recovered, due to economic and environmental issues.

Briefly, black liquor is withdrawn from the pulp in brown pulp washing systems

and then evaporated, so that it is concentrated, and its product is burned in

the recovery boilers. The solid residue of this stage is called dregs (FOELKEL,

2011).

The process characteristic with reuse

begins already in the boiler, where the steam produced is used in pulping and

papermaking, as well as for the production of electric energy for the factory.

After molten, the black liquor goes into a melt dissolution tank, forming the

green liquor which has as components sodium carbonate (Na2CO3)

and sodium sulfide (Na2S). Following the process occurs the

causticisation step, in which the sodium carbonate is placed in reaction with

lime (CaO) and gives rise to lime mud (CaCO3) and sodium hydroxide,

which can be reincorporated into the industrial process together with the

sodium sulfide to form the white liquor again (GOMIDE et al, 2006). The residue

from the preparation of hydrated lime, consisting mainly of lime mud is called

grits. The flow chart of the kraft recovery cycle can be seen in Figure 1.

Throughout the process, part of the

residues mentioned above and fluids from the production process generate

effluents that are conveyed to the effluent treatment plant. As is common in

effluent treatment processes, after the removal of the liquid portion of the

treated effluent, a semi-solid and pasty residue called effluent sludge is

generated. In pulp and paper industries, in addition to the residues mentioned

above, this sludge is also composed of a large concentration of cellulose which

makes it commonly called cellulose fiber, because of its physical and chemical

characteristics.

Figure 1 – Kraft

recovery cycle flowchart (GOMIDE et al, 2006)

Kraft pulp represents a large part of the

Brazilian pulp and paper sector, with South America being considered as the

largest producer of eucalypt kraft pulp in the world. This continent is

becoming the world's pole of production of eucalyptus pulp, so it is imperative

that South America lead research, innovation and development initiatives, not

only in the production and use of cellulosic pulp, but also in studies to the

reuse or treatment of solid wastes from their production, such as the aforementioned

disposal in the soil.

However, the disposal of residue of any

kind in the soil should not be carried out without first conducting studies in

order to take due account of possible changes in the physical and chemical

properties of the soil. Knowing the behavior of the material in the soil and

its implications is essential since the interactions with the medium result in

smaller or larger scale impacts to the biotic and abiotic environment.

Thus, with the objective of analyzing the

previous viability for the application of the cellulose fiber residue in the

soil, this study has as premise to carry out the classification of this residue

according to the norms and current legislation in order to classify the

hazardousness of the fiber of cellulose, determining whether there are

characteristics that make it a hazardous or non-hazardous, inert or non-inert

residue, as well as its behavior under solubilization and leaching tests.

2 Material and methods

The by-product assessed in this study

consists of residual fiber from cellulose manufacture. This recovered fiber are

residues from the industrial equipment, carried to the industrial wastewater

treatment plant. Since this residue is composed of a high concentration of

organic matter, it attracts attention to its use in the agriculture

The characterization of the residue of the

cellulose fiber, as the current legislation indicates, is an essential stage to

ensure the correct disposal and reuse of this residue. The chemical analysis

and classification were performed according to the recommended methodology

indicated by the Brazilian Association of Norms and Techniques (ABNT).

Therefore, to carry out the sampling, the

ABNT NBR 10007/2004 standard (ABNT, 2004a) was used, which determines the

standards for the sampling procedure of a representative amount of solid

residue, aiming to determine its characteristics regarding classification,

treatment methods, among others.

For the residue classification test, ABNT

NBR 10004/2004 (ABNT, 2004b) was used – Residue classification as to its

potential risks to the environment and public health, so that they can be

properly managed. This test analyses if the sample exhibits flammable,

corrosive, pathogenic and toxic characteristics.

The leaching test was carried out using the

ABNT NBR 10005/2004 standard (ABNT, 2004c) - Procedure for obtaining a leach

extract from solid residue that establishes the requisites required to obtain

this extract, in order to differentiate the residue classified by ABNT NBR

10004 /2004 as class I - hazardous - and class II - non - hazardous. The

leaching test was performed following the ABNT standards, in which a 100 g mass

of the sample was put in contact with 2000 mL of extraction solution 1 (5.7 mL

of glacial acetic acid, distilled and deionized water and 64.3 mL of 1.0 N NaOH,

made up to 1 L volume) for 18 ± 2 hours at 23 ± 2 ° C.

In the solubilization test, the reference

standard was ABNT NBR 10006/2004 (ABNT, 2004d) - Procedure to obtain a solubilized

solid residue extract, in order to differentiate the residues classified in

ABNT NBR 10.004 / 2004 as class II A - not inert - and class II B - inert. The

solubilization test was carried out according to the ABNT procedures, in which

a 250 g mass of the sample was put in contact with 1000mL of deionized water

for 7 days at a 23 ± 2 ºC temperature.

3 Results and discussion

The cellulose fiber characterization following

the ABNT NBR 10004/2004 standard showed that the residue did not present

flammability, reactivity, corrosivity, toxicity and pathogenicity

characteristics according to the terms considered by the standard. Therefore,

the sample was classified as non-hazardous (Class II). In terms of reactivity,

the presence of sulfide must be evaluated and the residue must present lower

than 500 mg of releasable H2S according to the United States

Environmental Protection Agency (USEPA) – SW 846 test methods, for the solid

waste evaluation test (USEPA, 2015). In our study we did not identified the

presence of sulfide.

It is important to mention that the

evaluation of sulfide in cellulosic fiber is of importance. Its occasional

presence in an residue is associated to the use of sulfur products in the

composition of the digestion liquor, causing secondary reactions with some

organic components that are present in the raw material, giving rise to the

organosulfides, gaseous materials that have an unpleasant odor. Besides the

hydrogen sulfide (H2S), other compounds are also considered organosulfurized

such as: methyl mercaptan (CH3SH), dimethyl sulfide [(CH3)2S]

and dimethyl disulfide [(CH3)2S2]. These

compounds make up a set called TRS (Total Reduced Sulfur) or reduced sulfur

compounds (MISHAL, 1975). These compounds are considered to be severe air

pollutants even at parts per billion (ppb) levels (OSSES, 1991). So, this

pollutant must be considered in studies involving waste reuse.

The determination of the transferability of

organic and inorganic substances present in the residues was carried out using

the leaching test determined by the ABNT NBR 10005/2004 standard, resulting in

a leached solution with pH of 5.47 after the contact period. For the results of

the leaching test, it can be inferred that none of the analyzed parameters are

above the maximum permitted value (MPV), conferring non-toxicity

characteristics, in the referred terms of the standard.

The solubilization test in the terms of the

ABNT NBR 10006/2004 standard, has the objective of identifying the

concentration of water-soluble substances. The results obtained for the

solubilization test are set out in the Table 1.

Table 1 – Determination

values of the solubilization test

|

Solubilization

Parameters

|

Obtained value

|

Unit

|

MPV

|

|

Aldrin + Dieldrin

|

<0.0003

|

mg/L

|

0.00003

|

|

Aluminum

|

0.412

|

mg/L

|

0.2

|

|

Arsenic

|

<0.002

|

mg/L

|

0.01

|

|

Barium

|

0.72

|

mg/L

|

0.7

|

|

Cadmium

|

0.022

|

mg/L

|

0.005

|

|

Lead

|

<0.002

|

mg/L

|

0.01

|

|

Cyanide

|

<0.005

|

mg/L

|

0.07

|

|

Chlordane

|

<0.0002

|

mg/L

|

0.0002

|

|

Chloride

|

7.023

|

mg/L

|

250

|

|

Copper

|

<0.006

|

mg/L

|

2

|

|

Chrome

|

<0.005

|

mg/L

|

0.05

|

|

2.4-D

|

<0.03

|

mg/L

|

0.03

|

|

DDT+DDD+DDE

|

<0.002

|

mg/L

|

0.002

|

|

Endrin

|

<0.0004

|

mg/L

|

0.0004

|

|

Phenols

|

0.74

|

mg/L

|

0.01

|

|

Iron

|

96.36

|

mg/L

|

0.3

|

|

Fluoride

|

<0.05

|

mg/L

|

1.5

|

|

Heptachlor Expoxide

|

<000003

|

mg/L

|

0.00003

|

|

Hexachlorobenzene

|

<0.001

|

mg/L

|

0.001

|

|

Lindane

|

<0.002

|

mg/L

|

0.002

|

|

Manganese

|

21.88

|

mg/L

|

0.1

|

|

Mercury

|

<0.0002

|

mg/L

|

0.001

|

|

Methoxychlor

|

<0.02

|

mg/L

|

0.02

|

|

Nitrate

|

0.335

|

mg/L

|

10

|

|

Silver

|

<0.002

|

mg/L

|

0.05

|

|

Selenium

|

<0.002

|

mg/L

|

0.01

|

|

Sodium

|

209.59

|

mg/L

|

200

|

|

Sulfate

|

149.775

|

mg/L

|

250

|

|

Surfactants

|

<0.10

|

mg/L

|

0.5

|

|

Toxaphene

|

<0.005

|

mg/L

|

0.005

|

|

2.4.5-T

|

<0.002

|

mg/L

|

0.002

|

|

2.4.5-TP

|

<0.03

|

mg/L

|

0.03

|

|

Zinc

|

0.192

|

mg/L

|

5

|

|

pH – Solubilized

|

6.45

|

-

|

-

|

*The lines highlighted in bold show the parameters

analyzed that extrapolated the maximum value by the ABNT NBR 10006/2004

standard

From the results obtained for the

solubilization test, the values found above the maximum permitted value for the

manganese, aluminum, barium, cadmium, phenols, iron, and sodium are

highlighted. This shows that the cellulose residue used in the study does not

present inert characteristics, that is, it demonstrates characteristics of

solubilization in water for some of its components, that way presenting a

potential of degradation or contamination of the water or the atmosphere.

Therefore, the waste is classified as class IIA (non-inert and non-hazardous)

The cadmium (Cd) concentration above the allowed

value may be related to the industrial machinery since this element is applied

for the steel and iron covering due to its high resistance to corrosion. It is

known that in the kraft process, the cadmium is found in low concentrations in

the raw materials and are removed by the liquor filtration system and by the

removal of dregs and grits (FOEKEL, 2011). The bioaccumulation potential of

cadmium in aquatic plants, invertebrates, fish, and mammals makes this an

element to be closely monitored, requiring attention to its final disposal.

The presence of phenols is often associated

by the pulping and papermaking process in the industry, due to the black

liquor, an effluent with high organic load generated in the kraft pulp process,

which is responsible for the removal of approximately 90% of the lignin present

in the wood (PERALTA-ZAMORA et al, 1997). The phenols determination before any

disposal of the residue is essential since this compound might be considered

toxic and potentially carcinogenic (SANTANA et al, 2009) and may affect the

taste and odor of drinking water even in low concentrations. At high

concentrations, phenolic compounds have destructive potential on aquatic fauna

and flora, due to its toxic characteristics and the high demand for oxygen.

For the pulp and paper industry, the

presence of manganese (Mn) is seen as a factor to be avoided in the production

process since, when mixed with iron (Fe) and copper (Cu), it causes negative

action on hydrogen peroxide stability, the substance used in acid washing for

cellulose bleaching. Manganese and iron can cause the catalytic decomposition

of hydrogen peroxide, generating hydroxyl radicals that attack and damage the

cellulose structure, reducing its physical properties (SIQUEIRA, SILVA FILHO

& SECCOMBRE, 2012).

The industries adopt chemical processes to

reduce the iron and manganese contents, so it is believed that the high values

recorded for these two parameters are related to their removal in the

production process, to their presence in the wood , water or even to their

generation by the equipment of the factory, causing them to be carried to the

treatment plant and consequent residue. For soil application, its known that

manganese is a nutrient and a limiting factor in the interaction with plants.

One of the main problems for soybean cultivation, for example, is Mn-deficient

soils (ROSOLEM et al., 1992). However, establishing critical levels of

manganese in the soil becomes difficult, since its soil determination is

strongly influenced by pH, and it is necessary to accomplish more specific

studies for the application of various manganese dosages on different pH

values.

For the aluminum levels (Al) observed, it

is known that the major inputs of this element in the kraft process industries

occur by the industrial water, by treatment using aluminum sulfate as a

flocculant, and by the limestone or lime used for the calcium replacement in the

lime system. Although most of it is precipitated by the recovery system and

collected by the green liquor filtration system (FOEKEL, 2011), some of the

aluminum may not be recovered and can be carried to the final residue of the

industrial process.

The special attention given to aluminum is

due to the fact that it is a neurotoxic compound with potential to cause damage

to human health when found in high concentrations. In the soil application,

studies report that although Al is not considered an essential element for

plant species, the application in low concentrations can stimulate the growth

of some plants, but on the other hand, if not applied in the correct

concentrations for each species, can cause cytological abnormalities in plants,

retarding the root growth (FERREIRA, MOREIRA & RASSINI, 2006).

The observed presence of sodium (Na) in the

solubilized has its main origin due to the use of compounds of this element in

the industrial process of lignin digestion and bleaching of the cellulosic

pulp. Although the kraft process presents low losses of sodium and sulfate due

to the mechanisms of recovery, it is estimated that the losses of these

elements are between 5 and 10%, which may justify the presence in the final

residue (FOELKEL, 2011).

A possible increase in the sodium

concentration in the soil due to the disposal of the residue shall be observed

with caution and demonstrates the necessity of monitoring, since with the

increase of the exchangeable Na+ content in the soil, some important

properties of the soil can be impaired from the agronomic point of view, such

as clay and organic substances dispersion (ALMEIDA et al, 2007). Another study

carried out with the disposal of residues with high sodium content in sandy

soils showed a higher susceptibility of the residues to the leaching of sodium

in the soil profile and could contaminate the groundwater (TRIGUEIRO, 2006).

The occurrence of barium (Ba) in pulp and

paper industries comes almost exclusively from wood and tree bark. Barium is an

element that demands special attention for the industries since its

precipitation as barium sulphate is one of the most undesirable in the fiber

line. This is due to the low solubility of the barium precipitate, making it

difficult to be removed mechanically or chemically, being a potential factor of

incrustations in the machinery of the industry (FOELKEL, 2011). Thus, the

precipitate is removed with the combination of mechanical treatments with

strong water jets, chelating agents, and acid washing, which can then carry concentrations

of this element up to the final residue of the production.

Although it is found naturally in the soil,

the high levels of barium can be toxic to plants and invertebrates, also

interfering with the sulfur availability, due to the formation of low

solubility sulfates (KUPERMAN et al, 2006). As for human health, it is known

that only 2% of ingested barium is absorbed by the body, tending to accumulate

in the bones, replacing calcium.

4 Final Considerations

The results obtained by the tests infer

that the residual fiber of pulp and paper industry presented values that do not

confer inert characteristics and classifies it as non-hazardous Residue Class

IIA. It is worth mentioning that the present study had the objective to carry

out the classification of the solid residue in question, to analyze and to seek

explanations for the values obtained, in order to characterize the residual

fiber and to serve as an input for the process of decision making on the

applicability of the residue in the soil.

Acknowledgements

The authors of this paper would like to

thank the support for this project provided by Universidade do Estado de Santa

Catarina (UDESC), Universidade do Oeste de Santa Catarina (UNOESC) and the

Laboratory of Water and Waste Treatment of CAV / UDESC.

References

ALMEIDA, H.C. et al. Influência da adição de um resíduo alcalino da Indústria de

papel e celulose na lixiviação de cátions em um solo ácido. Revista Brasileira de Ciência do

Solo. 2008; v32, n4, p.1775-1784.

ALMEIDA, H.C. et al. Composição

química de um resíduo alcalino da indústria de papel e celulose (Dregs). Química

Nova. 2007; v30, n7, p.1669-1672.

Associação

brasileira de normas técnicas. NBR 10007: Amostragem de resíduos sólidos.

Rio de Janeiro (Brazil): ABNT, 2004.

Associação

brasileira de normas técnicas. NBR 10004: Resíduos sólidos - classificação.

Rio de Janeiro (Brazil): ABNT, 2004.

Associação

brasileira de normas técnicas. NBR 10005: Procedimento para obtenção de

extrato lixiviado de resíduos sólidos. Rio de Janeiro (Brazil): ABNT, 2004.

Associação

brasileira de normas técnicas. NBR 10006: Procedimento para obtenção de

extrato solubilizado de resíduos sólidos. Rio de Janeiro (Brazil): ABNT, 2004.

BELLOTE,

A.F.J. et al. Resíduos

da indústria de celulose em plantios florestais. Colombo. 1998:

1-8.

FAVARO,

J.S.C. Estudos da polpação kraft, branqueamento de refino de Eucalyptus

grandis x Eucalyptus urophylla. [thesis].

Guaratinguetá: Curso de Engenharia Mecânica, Faculdade de Engenharia de

Guaratinguetá/Universidade Estadual Paulista; 2015. 180 f.

FERREIRA,

R.P.; MOREIRA, A; RASSINI, JB. Toxidez de alumínio em culturas anuais. Embrapa

Pecuária Sudeste-Documentos (INFOTECA-E), 2006.

FOELKEL,

C. Os eucaliptos e os elementos não processuais na fabricação de celulose

kraft. Eucalyptus

Online Book & Newsletter [Internet]. 2011. Available from: http://www.

eucalyptus. com. br/eucaliptos/PT24_ElementosNproces. pdf

GOMIDE, J.L. et al. Tecnologia e Química da Produção de Celulose. Viçosa:

Laboratório de Celulose e Papel, Universidade Federal de Viçosa; 2006: 235 p

KUPERMAN, R.G. et al. Toxicity benchmarks for antimony, barium, and beryllium determined

using reproduction endpoints for Folsomia candida, Eisenia fetida, and

Enchytraeus crypticus. Environmental toxicology and chemistry. 2006; v35, n3,

p.754-762.

MISHAL, B.T. Kraft pulping

and atmospheric gaseous emissions. IPTTA Souvenir. 1975: 95-103.

OSSES, M. Las emisiones de olores de una

planta de celulosa kraft. Celulosa y Papel. 1991: 6-16.

PERALTA-ZAMORA,

P. et al. Remediação de efluentes derivados da indústria de papel e celulose. Tratamento

biológico e fotocatalítico. Química Nova. 1997; 20 (2): 186-190.

ROSOLEM, C.A. et al. Manganês no solo, sua avaliação e toxidez de manganês em

soja. Pesquisa Agropecuária Brasileira. 1992; v27, n2, p. 277-285.

SANTANA, C.M. et al. Methodologies

for the Extraction of Phenolic Compounds from Environmental Samples: New Approaches. Molecules. 2009; 14: 298-320.

SIQUEIRA,

J.L.D; SILVA FILHO, LL.; SECCOMBE, R. Branqueamento de polpa kraft de

eucalipto-o papel do peróxido de hidrogênio. Peróxidos do Brasil

Ltda–São Paulo–SP, 2012.

TRIGUEIRO R.M. Efeito de “dregs e grits”

nos atributos de um neossolo quartzarênico e na produção volumétrica de

eucalipto [thesis]. Botucatu: Universidade Estadual

Paulista; 2006. 73 p.

USEPA, Environmental

Protection Agency. SW-846: Test Methods for Evaluating Solid Waste,

Physical/Chemical Methods. Washington (USA): USEPA, 2015.