1 Introduction

Meeting the demand

for good quality water for cities is one of the major current challenges.

Population growth, food production and industrial development can lead to

serious problems in water supply both in increasing demand for consumption and

in contamination of bodies of water. Agriculture consumes around 70% of the

world's water resources, followed by the industrial sector with 20% and the

domestic sector with 10%. These values may vary according to the country's

development (UNESCO,

2014).

Ensuring the

availability and sustainable management of water and sanitation for all is one

of the 17 sustainable development goals adopted in the General Resolution of

the United Nations in September 2015. This resolution known as Agenda 2030 in

its objective 6, subitem 6.3, mentions improving water quality, reducing

pollution, eliminating eviction and minimizing the release of hazardous

chemicals and materials (United Nations, 2015).

The use of

agrochemicals in agriculture has been intensified in recent decades with the

aim of increasing food production; on the other hand, these pesticides can be sources

of contamination for rivers and groundwater and, because of their intrinsic

nature, it can cause damages to human health that vary according to the active

principle and the absorbed dose (BRASIL,

2016).

Among the

pesticides, glyphosate is the most sold in the world. In Brazil alone,

glyphosate represents 40% of sales of pesticides. Glyphosate is an

organophosphorus, non-selective, systemic and post-emergent herbicide used in

many food and non-food crops, as well as non-agricultural areas, such as

recreational areas (WEIDENHAMER and CALLAWAY, 2010). Its physicochemical

properties are relatively low molecular weight, high polarity, high water

solubility, low solubility in organic solvents, amphoteric behavior, and easy

formation of metal complexes (SANCHIS et al., 2012).

In its early years,

it was believed that this herbicide, did not cause damage to human health but

with the intensification of its application in crops due to the development of

seeds resistant to this herbicide, new studies have pointed out the contrary (CARNEIRO

et al., 2015). One study showed that initial toxicity

tests indicated that glyphosate had low toxicity risks, prompting regulatory

authorities around the world to allow for high levels of exposure to

glyphosate; however, studies published in the last decade point to the need for

a new look at the toxicity of glyphosate. In addition, the authors state that

the International Agency for Research on Cancer, linked to the World Health

Organization, has recently concluded that glyphosate is "probably

carcinogenic to humans" (MYERS

et al., 2016; TARONE, 2018).

Other studies also

claim that glyphosate poses risks to human or other mammalian health such as: acute

and chronic neurotoxicity in rats(CATTANI

et al., 2014), neurodegenerative diseases such as

Parkinson's disease (GUI

et al., 2012) and endocrine problems in rats (CLAIR

et al., 2012).

The persistence and

transport of glyphosate in the soil are dependent on soil composition, climatic

conditions and microbiological activity, as well as agricultural management

(GIMSING et al., 2004). Most of the literature reports biological impacts of

glyphosate based on laboratory tests or short-term field studies (HELANDER et

al., 2012).

In addition, due to

the wide variety of application methods and climatic conditions, a significant

amount of glyphosate reaches the soil and may be leached from the root region

in drainage water and groundwater. Experimental observations combined with

transport studies suggest that the transport of glyphosate may occur due to

heavy rains shortly after application in moist soils leading to the formation

of preferential pathways flows (DAMONTE et al., 2007).

In this context,

one of the promising technologies for the removal of pollutants from water is

adsorption since it is a low cost and high efficiency method. Carbon-based

materials, such as graphene, have been extensively studied in adsorption

applications to remove contaminants from water due to their properties (CHOWDHURY

et al., 2014). One of the difficulties in the use of

adsorbent materials is its removal after the adsorption process. The

association of graphene with magnetic materials may facilitate such removal

work because the adsorbent material may be retained by a magnetic field without

the need for filtration or centrifugation (WANG

et al., 2015).

In comparison with

other materials formed by carbon, graphene has attracted the attention of

researchers due to its properties of an efficient association with metals and

metal oxides forming hybrids; this is owing to its properties of high

electrical conductivity, mechanical resistance and large specific area. Yao et

al. (2014) used a MnFe2O4 graphene hybrid as catalysts in

the removal of organic pollutants from water. Kumar et al. (2014) also used a

graphene oxide hybrid (MnFe2O4) in the removal of lead

and arsenic from contaminated water. The authors considered that the easy

magnetic separation, high removal efficiency, large surface area and the fact

of being reusable are factors that make this hybrid a strong candidate to be

used as a low cost adsorbent in the removal of toxic metals from water.

Specifically for

the removal of glyphosate from water, in a previous work it was synthesized,

characterized and tested the MnFe2O4-G composite

succeeding in removing this contaminant from water (YAMAGUCHI

et al., 2016). Although there are several recent studies

using magnetic graphene for water treatment, it was noticed that an industrial

application was not aimed, and it was used batch scale laboratorial assays with

different equipment for each step of the processes.

This whole scenario

motivated a previous research for the development of a prototype in a pilot

scale using the MnFe2O4-G composite. The results were

satisfactory, the prototype was evaluated in relation to the removal of

glyphosate in four complete cycles of adsorption and desorption, obtaining a

84.5% removal of glyphosate in the first cycle, 80% in the second and third

cycle and 60% in the fourth cycle (SANTOS et al., 2017).

Therefore, the

proposal addressed in the present research had as objective the design and

construction of a single prototype that gather all the steps of water

decontamination with glyphosate using a hybrid compound of MnFe2O4-G,

aiming to provide a concept for applications in water treatment plants. Thus,

it was focused the determination of the steps to glyphosate removal, the

definition of the layout, the selection of materials, the project elaboration,

the construction of the prototype in a reduced scale.

2 Materials and methods

2.1

Determination of the steps for the removal of glyphosate using hybrid manganese

ferrite compound and graphene

Initially, the

volume of 1 dm3 of water was assigned to be treated. After that, it

was necessary to determine the steps for the treatment of water contaminated

with glyphosate, in order to design the prototype. For that, it was used the

work developed by Yamaguchi et al. (2016) and Santos et al. (2017) for the

determination of these steps and analysis methods.

The first step of

the process was to place 1.0 g of particles in contact with glyphosate

contaminated water (20 ppm) and stirred them for a period of 5 hours in order

to perform the adsorption. In this way, the first part of the prototype worked

with a tank coupled with a stirrer. This step was called the adsorption step.

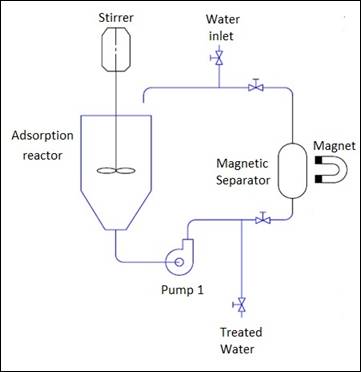

After the

adsorption step, the particles had to pass through a magnetic field to be

separated from the water that was decontaminated. A magnetic separator

connected in parallel with the adsorption reactor was designed as shown in

Figure 1. In that separator, a magnetic field was approached or moved away from

the walls of the reservoir according to the need for separation. The flow

velocity was reduced and the water was pumped from the adsorption reactor to

the magnetic separator and returned to the adsorption tank. As a result, the

water passed several times through the magnetic field for a better retention of

the particles. In order to measure the efficiency of the magnetic separator,

the MnFe2O4-G particles were weighed at the beginning of

the experiment and at the end of all 4 cycles. This

step was called magnetic separation.

Figure 1 - Flow diagram of the

adsorption reactor and magnetic separator

After the magnetic

separation, the decontaminated water was drained and discarded. In an

industrial-scale situation, this water could be referred to other treatments

according to the necessity.

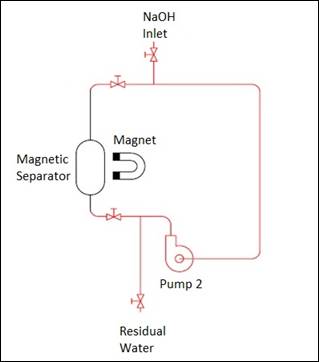

After this first

magnetic separation, the particles contaminated by glyphosate were retained in

the separator and must undergo a desorption process so that the contaminant is

removed from the particles, allowing them to be reused in new cycles of adsorption.

In the desorption process, the particles were contacted with a solution of 0.1

M NaOH and stirred for a period of time empirically defined in 15 minutes. For

this purpose, the same magnetic separator reservoir was used, this time without

the magnetic field, and a pump was used as a stirrer, as shown in Figure 2. The

desorption was completed and the particles were again magnetically

Figure 2 - Flow diagram of the

desorption system

After desorption,

these particles were rinsed with pure or distilled water to remove the excess

of NaOH to which the particle had been exposed. This rinsing was performed in

the same manner as in the desorption using the magnetic separator resevoir

without the field and a 10 minute empirically assigned time bomb.

The rinsing step

may be performed more than once to ensure maximum removal of NaOH. After each

rinsing step, a new magnetic separation was performed, the rinse water was

discarded, and the MnFe2O4-G particles were ready for

further treatment processes. This stage was called rinsing.

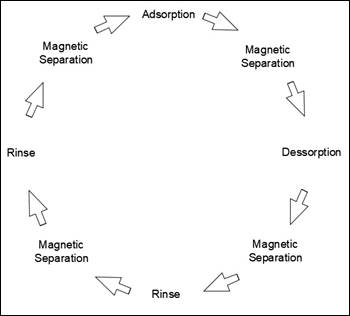

All steps were

cited and were performed in a predetermined order, according to the flowchart

shown in Figure 3.

Figure 3 - Flowchart with all

treatment steps

2.2

Definition of materials

The first

components to be acquired were the pumps. For this, since the prototype should

treat the volume of 1 dm3 of water, it was attributed that the pump

to be selected should have a flow rate of around 5 dm3min-1.

For a better control of the flow, the pump should be fed by direct current of

electricity; therefore, by varying the voltage of the pump, it would be possible

to vary the flow rate.

The adsorption

reactors and magnetic separator were made from PET bottles, with a volume of

1.5 dm3 for the adsorption reactor and 0.1 dm3 for the

magnetic separator. The hoses used were of silicone, 10 mm and transparent.

The magnets

selected for the magnetic separator were neodymium, type N52, with dimensions

of 40x20x10 mm.

To facilitate the

assembly, 10 mm pneumatic connections have been chosen so that the hoses could

be fastened and de-attached quickly like a quick coupling. Mass and epoxy resin

were used to fix the connections in the reservoirs.

3 Results and discussion

3.1

Prototype design

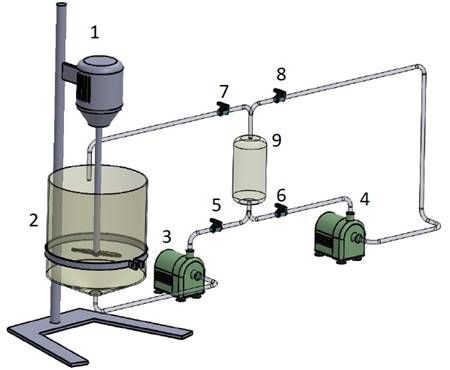

Figure 4 shows the layout defined for the construction of the prototype.

Note that the two systems that make up the removal process are present and

interconnected. On the left side of the layout is the glyphosate adsorption

system and on the right side, the particle regeneration system (desorption).

This was the initial proposition for setting up the prototype. Nonetheless, the

adsorption and desorption processes were not constructed interconnected in this

first moment. They were constructed separately but the interconnection can be

easily accomplished by means of valves as shown in Figure 4.

Figure 4 - Prototype and its components:

1 stirrer; 2 adsorption reactor; 3 and 4 pumps; 5, 6, 7 and 8 valves; 9

magnetic separator

3.2

Construction of the prototype

In Figures 5 and 6, it is possible to observe the constructed prototype

and being tested in the laboratory. Figure 5 shows the layout with the

configuration projected next to the built prototype, showing the adsorption

step. It also shows that the propeller stirrer was not required inside the

adsorption reactor, due to the fact that the selected and installed pump performed

the agitation of the particles successfully. Another modification concerns the

entry of water into the system, which in the initial layout should be performed

by a pipe. The water inflow into the system was carried out directly over the

upper inlet of the reactor, by manually supplying 1 dm3 of

artificially contaminated water with 20 ppm of glyphosate.

Figure 5 - Original layout alongside

the built prototype with the steps of adsorption and magnetic separation

It is further noted that the output of the treated water, which in the

original layout would be between the pump and the magnetic separator by means

of piping, occurred just before the magnetic separator by simply disconnecting

the hose before entering the separator. It is suggested, for later studies,

that all components of the original layout are connected, except the agitator

which proved to be unnecessary, just to make the system configure itself with a

better presentation. In terms of removal efficiency, it should be noted that the

simplifications adopted did not compromise the results.

Figure 6 shows the layout with the configuration designed next to the

built prototype, showing the desorption stage of the particles. As previously

explained, the entry of NaOH into the system and the exit of the waste water,

which in the initial layout should be performed by a suitable piping, occurred

just before the magnetic separator by simply disconnecting the hose.

Figure

6 - Original layout next to the prototype built with the adsorption and magnetic

separation steps

After the construction of the prototype, some tests of its operation were

carried out in order to identify possible leaks and other problems not foreseen

in the project.

3.3

Prototype test

A test was performed to verify the prototype's functioning and correction

of possible problems such as leaks. Regarding the magnetic separation, it was

found empirically that within 15 minutes the separation was completed and 70%

of the particles were recovered after 4 complete cycles of treatment, while 30%

of the particles were lost in the treated water in the regeneration NaOH

solutions, in the waters of rinsing and part were deposited in the walls of the

tanks and pipes.

The feasibility of use and regeneration of the material in the prototype was

also evaluated in an earlier study (SANTOS et al., 2017). The results showed that the treatment is

promising, since there was significant water decontamination in four complete

cycles, with 84.5% of glyphosate removal in the first cycle, 80% in the second

and third cycle and 60% in the fourth cycle.

A previous work (YAMAGUCHI et al., 2016) has also studied the magnetic

graphene composite, MnFe2O4–G. The material was was

characterized using various techniques, and then applied to remove glyphosate

from water in batch scale experiments. The results showed that the hybrid

composite presented a BET area of 305.5 m2/g and was well dispersed

on graphene nanosheets. It was also proposed that the adsorption mechanism of

glyphosate on MnFe2O4–G was through a combination of an

electrostatic interaction with an ion exchange that was favoured at low

temperature. The maximum adsorption capacity of glyphosate adsorption was 39 mg

g-1 at 5°C. The kinetics and isotherm data obtained fitted well with

pseudo-second-order kinetics and the Freundlich isotherm model, indicating a

multilayer chemisorption in a heterogeneous surface. It was also determined that

the adsorption of glyphosate on the MnFe2O4–G was spontaneous

and exothermic.

There are few studies of glyphosate removal from aquous solutions in the

literature. Some works studied the adsorption of glyphosate herbicide on

activated carbon and biochar. Mohsen et al. (2010) obtained a maximum

adsorption capacity of 48.4 mg g-1 in activated carbon derived from

a newspaper industry waste. Mayakaduwa et al. (2015) determined the kinetic and

equilibrium mechanisms for the adsorption of glyphosate by biochar and obtained

a maximum adsorption capacity of 44 mg g-1. Both results were

slightly higher when compared with the maximium adsorption capacity of MnFe2O4–G

(39 mg g-1) (YAMAGUCHI et al., 2016). However, the advantage of MnFe2O4–G

is its application in a prototype presenting all the steps of adsorption and

desorption for glyphosate decontamination in the same equipment using its

capability of reusability and magnetic separation.

4 Conclusion

The prototype was

conceived and designed with its components, materials and layout defined. After

constructing the prototype, it was possible to achieve the goal of bringing all

the treatment steps together into a single device, although at the moment it has

been built in two parts separately, which can be solved with the use of valves.

The tests were performed according to what was proposed and no operational

problems were identified. Although the recovery of the particles in the

magnetic separator has been satisfactory, improvements in this separation can

be developed in other studies. Additional tests may be performed for future

work for better understanding of the process, such as pH, replicates,

optimization of stirring speed, adsorption and desorption times, costs of the

processes, reusability of the adsorbent, use of different contaminants and the

use of real wastewaters. Also full-scale studies are recommended in order to

apply the concepts in a water treatment plant.

References

BRASIL. Relatório

Nacional de Vigilância em Saúde de Populações Expostas a Agrotóxicos.

Brasilia: Ministério da Saúde, p.141, 2016

CARNEIRO,

F. F.; AUGUSTO, L. G. D. S.; RIGOTTO, R. M.; FRIEDRICH, K.; BÚRIGO, A. C. Um

alerta sobre os impactos dos agrotóxicos na saúde. Rio de

Janeiro/São Paulo: EPSJV Editora Expressão Popular 2015.

CATTANI,

D.; CAVALLI, V.; RIEG, C. E. H.; DOMINGUES, J. T.; DAL-CIM, T.; TASCA, C. I.;

SILVA, F.; ZAMONER, A. Mechanisms underlying the neurotoxicity induced by

glyphosate-based herbicide in immature rat hippocampus: Involvement of

glutamate excitotoxicity. Toxicology, v.

320, n., p. 34-45, 2014.

CHOWDHURY,

S.; BALASUBRAMANIAN, R. Recent advances in the use of graphene-family

nanoadsorbents for removal of toxic pollutants from wastewater. Advances in

Colloid and Interface Science, v. 204, n. Supplement C, p. 35-56, 2014.

CLAIR,

É.; MESNAGE, R.; TRAVERT, C.; SÉRALINI, G.-É. A glyphosate-based herbicide

induces necrosis and apoptosis in mature rat testicular cells in vitro, and

testosterone decrease at lower levels. Toxicology in Vitro, v. 26, n. 2,

p. 269-279, 2012.

DAMONTE,

M.; TORRES SÁNCHEZ, R. M.; DOS SANTOS AFONSO, M. Some aspects of the glyphosate

adsorption on montmorillonite and its calcined form. Applied Clay Science,

v. 36, n. 1–3, p. 86-94, 2007.

GIMSING,

A. L.; BORGGAARD, O. K.; BANG, M. Influence of soil composition on adsorption

of glyphosate and phosphate by contrasting Danish surface soils. European

Journal of Soil Science, v. 55, n. 1, p. 183-191, 2004.

GUI,

Y.-X.; FAN, X.-N.; WANG, H.-M.; WANG, G.; CHEN, S.-D. Glyphosate induced cell

death through apoptotic and autophagic mechanisms. Neurotoxicology and

Teratology, v. 34, n. 3, p. 344-349, 2012.

HELANDER,

M.; SALONIEMI, I.; SAIKKONEN, K. Glyphosate in northern ecosystems. Trends

in Plant Science, v. 17, n. 10, p. 569-574, 2012.

KUMAR,

S.; NAIR, R. R.; PILLAI, P. B.; GUPTA, S. N.; IYENGAR, M. A. R.; SOOD, A. K.

Graphene Oxide–MnFe2O4 Magnetic Nanohybrids for Efficient Removal of Lead and

Arsenic from Water. ACS Applied Materials & Interfaces, v. 6, n. 20,

p. 17426-17436, 2014.

MAYAKADUWA,

S. S.; KUMARATHILAKA, P.; HERATH, I.; AHMAD, M.; AL-WABEL, M.; OK, Y. S.;

USMAN, A.; ABDULJABBAR, A.; VITHANAGE, M. Equilibrium and kinetic mechanisms of

woody biochar on aqueous glyphosate removal. Chemosphere, v., n., p.,

2015.

MOHSEN

NOUROUZI, M.; CHUAH, T. G.; CHOONG, T. S. Y. Adsorption of glyphosate onto

activated carbon derived from waste newspaper. Desalination and Water

Treatment, v. 24, n. 1-3, p. 321-326, 2010.

MYERS,

J. P.; ANTONIOU, M. N.; BLUMBERG, B.; CARROLL, L.; COLBORN, T.; EVERETT, L. G.;

HANSEN, M.; LANDRIGAN, P. J.; LANPHEAR, B. P.; MESNAGE, R.; VANDENBERG, L. N.;

VOM SAAL, F. S.; WELSHONS, W. V.; BENBROOK, C. M. Concerns over use of

glyphosate-based herbicides and risks associated with exposures: a consensus

statement. Environmental Health, v. 15, n., p. 13, 2016.

SANCHIS,

J.; KANTIANI, L.; LLORCA, M.; RUBIO, F.; GINEBREDA, A.; FRAILE, J.; GARRIDO,

T.; FARRE, M. Determination of glyphosate in groundwater samples using an

ultrasensitive immunoassay and confirmation by on-line solid-phase extraction

followed by liquid chromatography coupled to tandem mass spectrometry. Anal

Bioanal Chem, v. 402, n. 7, p. 2335-2345, 2012.

SANTOS,

J. C. M.; SOUSA, J. C. A.; ALMEIDA, A. C. S.; HOMEM, N. C.; BERGAMASCO, R.;

GASPAROTTO, F.; REZENDE, L. C. S. H.; YAMAGUCHI, N. U. Pilot Batch-Scale

Reactor for Glyphosate Removal Using Hybrid Magnetic Graphene. Chemical

Engineering Transactions, v. 60, n., p. 6, 2017.

TARONE,

R. E. On the International Agency for Research on Cancer classification of glyphosate

as a probable human carcinogen. European Journal of Cancer Prevention,

v. 27, n. 1, p. 82-87, 2018.

UNESCO.

The United Nations World Water Development Report 2014: Water and

Energy. Paris: 2014

UNITED

NATIONS. Transforming our world: the 2030 Agenda for Sustainable

Development. 2015.

Disponível em

http://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E. Acesso

em 08/03/2018.

WANG,

H.; YUAN, X.; WU, Y.; CHEN, X.; LENG, L.; WANG, H.; LI, H.; ZENG, G. Facile

synthesis of polypyrrole decorated reduced graphene oxide–Fe3O4 magnetic

composites and its application for the Cr(VI) removal. Chemical Engineering

Journal, v. 262, n. Supplement C, p. 597-606, 2015.

WEIDENHAMER,

J. D.; CALLAWAY, R. M. Direct and indirect effects of invasive plants on soil

chemistry and ecosystem function. J Chem Ecol, v. 36, n. 1, p. 59-69,

2010.

YAMAGUCHI,

N. U.; BERGAMASCO, R.; HAMOUDI, S. Magnetic MnFe2O4–graphene hybrid composite

for efficient removal of glyphosate from water. Chemical Engineering Journal,

v. 295, n. Supplement C, p. 391-402, 2016.

YAO,

Y.; CAI, Y.; LU, F.; WEI, F.; WANG, X.; WANG, S. Magnetic recoverable MnFe2O4

and MnFe2O4-graphene hybrid as heterogeneous catalysts of peroxymonosulfate

activation for efficient degradation of aqueous organic pollutants. Journal of

Hazardous Materials,

v. 270, n. Supplement C, p. 61-70, 2014.